Inseto Publishes New Case Study on MEMS Sensor and Microelectronics R&D

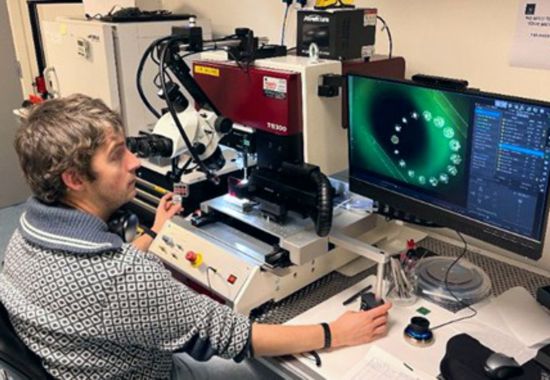

Inseto has published a new case study showing how the Tresky T-5300 semiautomatic die bonder is supporting advanced research into MEMS sensor devices and next-generation microelectronic assemblies.

The organisation featured is carrying out early-stage development that demands high-precision die placement, consistent bond-line control and the flexibility to handle a wide variety of die geometries and materials. The T-5300’s design—centred on True Vertical Technology™, a motorised, programmable Z-axis and a highly adaptable tooling platform—proved an excellent fit.

Key outcomes include:

-

Improved placement accuracy for prototype MEMS structures

-

Reduced process variability during adhesive and low-temperature bonding

-

Faster iteration cycles through flexible tooling and rapid setup changes

-

Reliable handling of irregular die shapes and heterogeneous integration tasks

The case study shows how the T-5300 enables researchers to validate assembly parameters during R&D before moving to automated production equipment.

Read the full case study: https://www.inseto.com/equipment/manual-die-bonders-by-tresky-ag/tresky-t-5300-semiautomatic-die-bonder/research-and-development-of-mems-sensor-devices-and-advanced-microelectronics/

Visit the Inseto (UK) Ltd website for more information on Inseto Publishes New Case Study on MEMS Sensor and Microelectronics R&D