Owner-Operators Shifting Toward Cost-Effective Spares & Repairs

As wind turbine fleets age, OEMs and owner-operators are increasingly prioritising cost-effective spares, repairs, and life-extension solutions.

Long lead times, component obsolescence and ageing assets are fuelling demand for engineered repairs, lifecycle upgrades and regionally focused supply chains. Technical partnerships are becoming essential to cut downtime, manage obsolescence and defer capital expenditure.

Key outcomes include:

-

Lower total cost of ownership through engineered repairs

-

Reduced downtime with emergency spares available within practical time frames

-

Extended turbine life via retrofit programmes, adding years of operation

-

Stronger local supply chains and technical partnerships

The UK market is approaching a major transition. With many onshore and offshore projects nearing 20 years in service—and typical end-of-life horizons of 20–25 years—significant life-extension and decommissioning decisions will be required over the next decade.

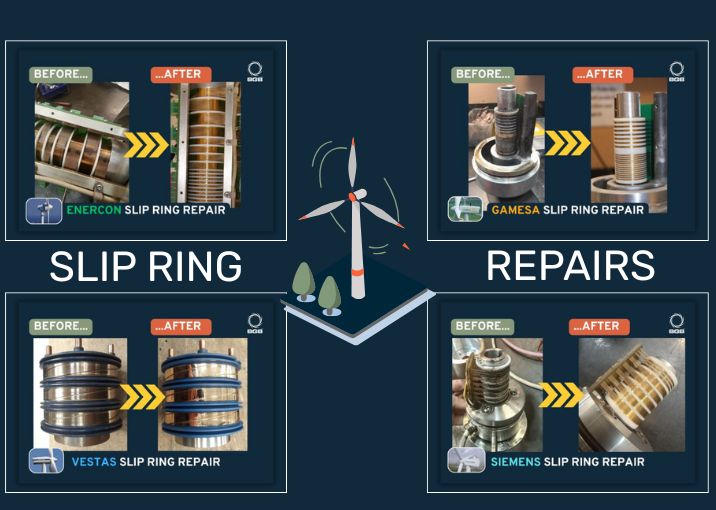

Our dedicated Repairs and Upgrades team regularly refurbishes slip ring units built with now-obsolete non-BGB parts. Using our engineering expertise, we rebuild with BGB-designed components to restore function, improve performance and extend the life of legacy wind turbines.

Visit the BGB website for more information on Owner-Operators Shifting Toward Cost-Effective Spares & Repairs