Common Causes of Wind Turbine Failures (and How to Prevent Them)

Wind turbines operate in some of the harshest environments, where failure can lead to costly downtime and extensive repair work. That’s why proactive maintenance and dependable components are vital to ensuring long-term performance.

Failures may arise from mechanical wear, electrical faults or environmental stress. While not all issues can be completely avoided, their impact can be significantly reduced with high-quality components, routine servicing and early intervention.

Below, we outline the most common causes of wind turbine failure and highlight practical steps to minimise their effects.

Common causes of wind turbine failures

Blade damage

Among the most common failure types, blade damage can result from extreme weather such as hail, lightning or strong winds, as well as impact from debris or material fatigue over time. Even minor surface cracks can develop into serious structural problems if left undetected.

How to reduce risk:

Frequent inspections using drones or ground-based sensors can help detect issues early. Protective coatings and lightning protection systems also improve resilience to environmental stresses.

Gearbox failures

The gearbox is critical in converting the low-speed rotation of the blades into high-speed motion needed for electricity generation. Failures here are typically linked to lubrication breakdown, wear and tear or manufacturing defects, making it one of the most maintenance-intensive components.

How to reduce risk:

Implement condition monitoring, including oil analysis and vibration sensors. Use high-quality materials and ensure correct alignment to prolong lifespan and improve reliability.

Electrical failures

Generators, transformers and control systems can all fail due to overheating, electrical surges, insulation breakdown or age-related wear.

How to reduce risk:

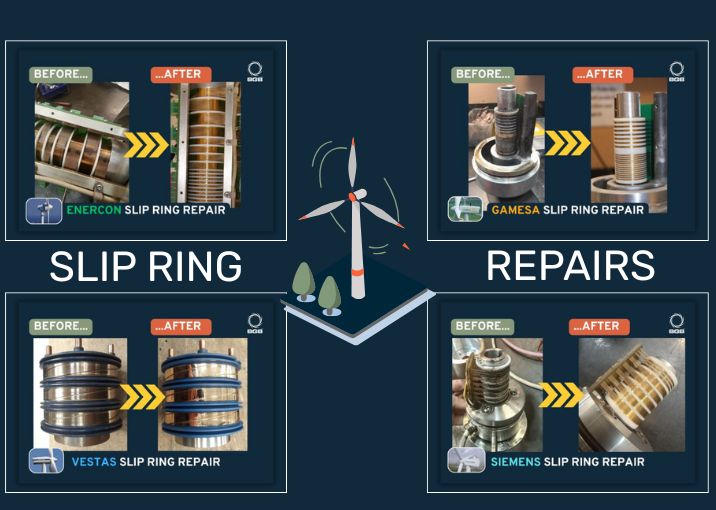

Use robust, high-performance components to ensure stable power and signal transmission. BGB’s slip rings, for instance, are engineered to withstand vibration, temperature extremes and moisture, minimising electrical faults in rotating assemblies.

Yaw system failures

The yaw system enables the turbine to align with the wind. If this mechanism fails, efficiency drops and components may suffer from off-axis forces.

How to reduce risk:

Regularly inspect and calibrate motors, gear systems and sensors. Monitor data continuously to identify any positional anomalies early on.

Structural failures

Damage to the tower, nacelle or foundation often stems from fatigue, corrosion, poor design or environmental impact.

How to reduce risk:

Conduct routine inspections using non-destructive methods such as ultrasonic testing or thermal imaging to identify early signs of weakness or cracking.

Overloading

Operating beyond a turbine’s rated wind speed capacity can place excessive stress on the drivetrain and other internal components.

How to reduce risk:

Ensure that turbine control systems can respond rapidly to changing conditions by feathering blades or shutting down when needed. Maintaining accurate sensors and reliable software is essential.

Bearing failures

Bearings in the hub and gearbox are subject to constant load and rotational stress. Contamination, poor alignment and inadequate lubrication often lead to premature failure.

How to reduce risk:

Use sealed bearings where possible and monitor temperature and vibration regularly to detect potential issues early.

Poor maintenance

Inconsistent or poor maintenance is a leading factor in turbine failure. Missed inspections and improper repairs allow minor faults to escalate.

How to reduce risk:

Follow a structured, data-led maintenance plan. For example, slip rings should be checked, cleaned and replaced at regular intervals to maintain performance.

Corrosion

Offshore and coastal turbines face constant exposure to salt air, humidity and condensation, all of which accelerate corrosion.

How to reduce risk:

Use corrosion-resistant materials and IP-rated sealed enclosures. BGB’s slip rings are specially developed to operate reliably in these conditions.

Control system faults

Control systems manage pitch, yaw, braking and more. Malfunctions can occur due to software errors, faulty sensors or signal transmission issues.

How to reduce risk:

Keep firmware up to date and use high-quality components to maintain accurate, consistent performance.

Boosting turbine performance with BGB

At BGB, we offer custom-engineered slip rings and deep expertise in rotary systems to help OEMs and wind farm operators improve turbine reliability and efficiency. Our components are built to withstand high vibration, extreme temperatures and moisture ingress, helping reduce downtime and extend the lifespan of your equipment.

Explore our full product range or contact us today to discuss bespoke solutions tailored to the demands of wind energy.

Visit the BGB website for more information on Common Causes of Wind Turbine Failures (and How to Prevent Them)