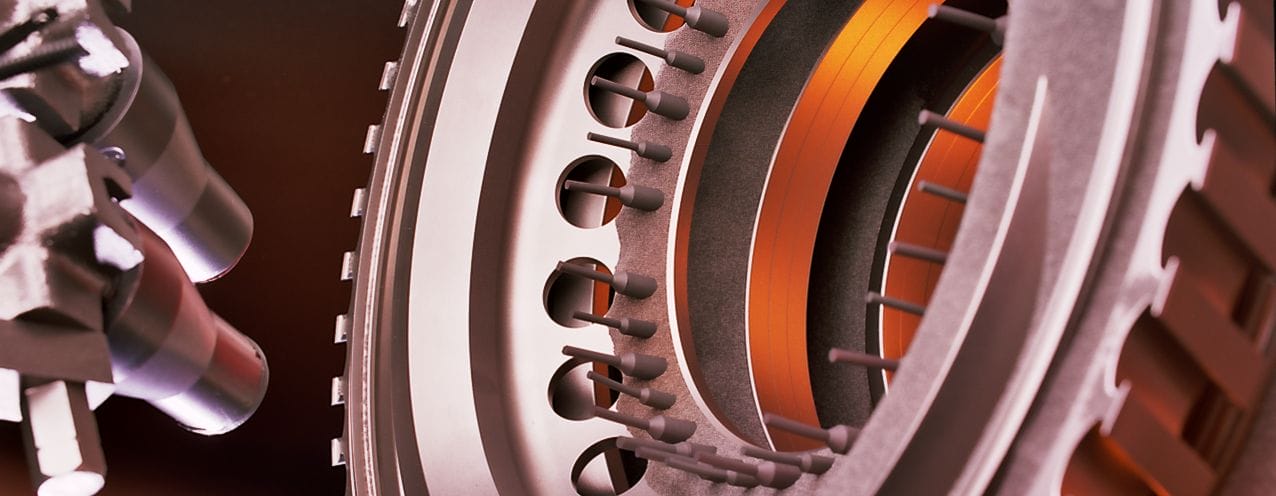

Laser Peening For Turbine Blade Fatigue Resistance

Laser Peening For Turbine Blade Fatigue ResistanceProfessional laser peening services apply high-energy shock waves to metal surfaces to induce deep compressive stresses that delay crack initiation, improve fatigue strength, and extend service life of critical components. Ideal for aerospace, power generation, and industrial applications, this precision surface enhancement increases durability and resistance to stress corrosion and wear.

Visit the Curtiss Wright Surface Technologies website for more information on Laser Peening For Turbine Blade Fatigue Resistance